UltraTester™ Machine Effectively Tests and Compares Dental and Orthodontic Adhesives

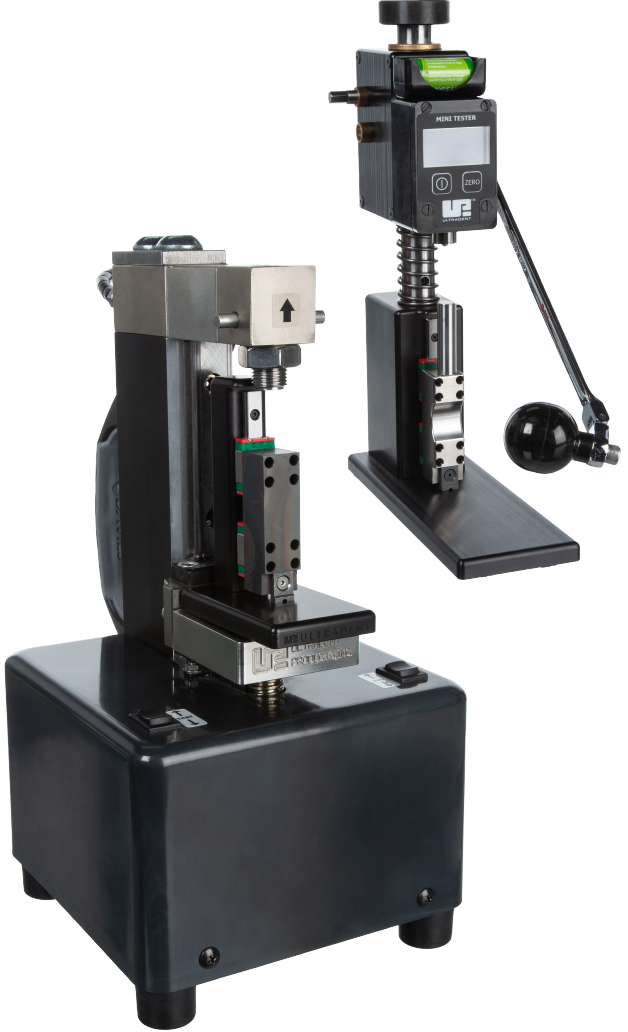

The UltraTester and MiniTester have been designed and created to capture peak compressive values applied to testing materials. Where the UltraTester is motorized and is able to apply and capture loads up to 750 lbs with adjustable speed control (0.1-25mm/min) for addressing loading rate, the Mini tester has been designed with portability in mind and is able to apply and capture loads up to 150 lbs. Both machines utilize precision linear slides to apply the loading forces, which is of utmost importance for capturing accurate data on rigid materials.

The manual loading lever on the MiniTester allow for very efficient test processing with a short learning curve, so that when teaching large groups, one is better able to keep the group engaged in the subject matter without as much waiting and set-up time. The MiniTester is ideal for Shear Bond Testing but can be adapted for use with other tests. The UltraTester, with its higher load capacity is able to perform many loading type tests commonly used in dentistry, from the Shear Bond Test which normally ranges up to about 70 lbs as well as higher force demands, such as the compressive tests on the smaller specimens used in the UPI compression method, which commonly range up to about 550 lbs.

While both machines have been evaluated against common high-priced equipment and are proven to generate similar results, each machine has unique benefits which can benefit your educational and research needs.

The UltraTester machine is intended for research purposes only.

Downloads

UltraTester Machine Price SheetFor more information or to order an UltraTester machine, please contact Wendy Groen:

wendy.groen@ultradent.com 801.553.4351For international orders, please contact Phyllis Thibodeau:

phyllis.thibodeau@ultradent.com 801.553.4122| Metric | Ultratester | Mini Tester | Linear Slide |

|---|---|---|---|

| Load Range | 0-340 kg | 0-68 kg | N/A |

| Accuracy | 1% | 1% | N/A |

| Speed Range | 0-25 mm/min | Manual | N/A |

| Weight | 6.35 kg | 2 kg | 367 g |

| Height | 33 cm | 26 cm | 10 cm |

| Width | 17.8 cm | 6.35 cm | 8.25 cm |

| Depth | 17.8 cm | 17.8 cm | 8.25 cm |

| Platen / Slide Travel | 63.5 mm | 22 mm | 22 mm |

| Max Distances Between Load Cell and Test Platen | 127 mm | 22 mm | 22 mm |

| Platen Dimensions | 50 mm x 50 mm x 15.8 mm | N/A | N/A |

| Power Supply | 110/220 | CR123A Battery | N/A |

Parts

Bonding Clamp and Bonding Mold Inserts

The bonding clamps are able to function for years with normal use. The mold inserts are made of injection-molded polypropylene, which allows for a highly polished and uniform internal surface, so the composite can polymerize without substantial adhesion. The molds are semi-disposable and will generally last between 50-100 uses. The mold has been designed so that only a 0.1 mm rim touches the tooth, allowing for quality isolation of the bond site to be achieved.

Test Base Clamp

The test base clamp holds the prepared specimen in place on the UltraTester machines during testing.

Linear Slide Shear Contact

The Ultradent Linear Test Slide is a valuable tool for testing Shear Bond Strength. We've found that the major contributors to precision repeatability of the Shear Bond Test are first that a precision Shear Noticed is used. The Shear Notch has been manufactured to exacting tolerances with > +/-5 microns deviation on the diameter. Another large effect on shear data is influence by the linear movement of the Shear Notch. If the loading motion has flex or wobble during the test we find that the data is highly erratic and makes it difficult to assess the true strength of the adhesive. The Linear Test Slide is small and compact and is able to be used on all types of universal testing machines, helping to reduce the artifacts of non-linear motion. We find that once the precision Shear Notch and a precision Linear Slide are used that we are easily able to replicate bonding values from one laboratory to another. Unless this tool or any equivalent tool is used, it is unlikely that a researcher will be able significantly reduce the deviation in the shear test and will always be challenged with determining if the results are material or technique driven. This tool helps to solve this serious problem.

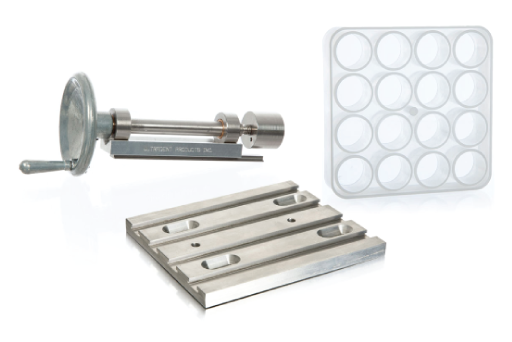

Grinding Assembly Kit

The grinding assembly kit includes five 16-hole molds for casting methacrylate cylinders to embed teeth or other dental substrates. The mold produces cylinders measuring 1 inch in diameter by 1 inch in length. The cylinders are then ground to produce parallel surfaces and to remove any unwanted debris using the grinding mandrel. The grinding mandrel is designed to receive the 1 inch cylinder and allow the technician to press it against a model trimmer/grinder while rotating the cylincer to produce a random grinding pattern on the surfaces. The mandrel is held secure in a T-slot grinding plate, which is intended to be mounted to a model trimmer's working table.